Early manufacturing ingenuity has some legendary golf balls selling in the tens of thousands.

By Dick McDonough

GCS Bulletin, December 2017

The golf ball and its development have had a more profound impact on golf than any other implement of the game. Innumerable articles and books have been written about golf ball innovation from the wooden ball, to the feather ball, to the gutta-percha, and finally the rubber core ball. As the golf ball improved, golf courses needed to be lengthened, until finally in 1941 the ball became strictly regulated by the USGA.

Here, we’ll trace seminal changes made over several centuries with an emphasis on the experimental period around the turn of the 19th century. At that time golf ball manufacturers produced balls with dozens of unusual and exotic cover patterns before settling on the dot or dimpled face, now the universal standard. Several old patterns are so rare that avid collectors have been willing to pay tens of thousands of dollars for a single ball.

The Wooden Ball

Gowf, goff, goffe, gouff or golfe was played as early as the 1400s in Scotland. No one knows for certain, but the balls were most likely a hardwood such as beech or boxwood. Interestingly, several ancient European stick and ball games – chole, crosse, jeu de mail, pall mall, and colf – all used wooden balls of various sizes and shapes. A wooden ball called a “soulette” is still used in Belgium in the game of chole.

The Feather Ball

From roughly the 1600s until about 1850 golf was played with a ball of a stitched leather covering, typically horsehide or bullhide, that was filled with boiled goose or chicken feathers that had been soaked in brine. The equivalent of a top hat of boiled goose feathers would be stuffed through an opening of a leather pouch, then stitched shut. When the feathers dried, along with the leather, they expanded, creating a tough and hard leather ball – the featherie. Ball makers could only produce a handful daily, so the balls were expensive and golfers could not afford to lose them. Though initially tough, the balls would soften with use, especially in damp or rainy conditions. Wooden clubs with long, slender, shallow heads and a small face, known as long nose clubs, were preferred over iron clubs due to the risk of cutting the ball. The average length of a feather ball drive was in the range of 150-175 yards, but under perfect conditions a drive of 361 yards was recorded at St Andrews.

The Gutta Percha Ball

Gutta percha is a rubber-like material of dried sap from the sapodilla tree of East Asia. In 1845, Rev. James Paterson of Dundee, Scotland, took delivery of a religious statue packed in gutta percha. His son, Rob, inspired by who knows what, boiled the gutta percha and then shaped it into a round ball. He took the newly formed ball and his clubs out to the Old Course, and the gutta percha ball, or guttie, was born. Others began to experiment with the substance and by 1850 it became the ball of choice in large measure because it sold for a fraction of a feather ball’s price. Interestingly, Rob Paterson, responsible for one of golf’s greatest innovations, never realized how he had changed the game because he emigrated to Binghamton, N.Y. long before golf made its appearance in the U.S.

Given the history of the rounded feather ball, it is not surprising that initially gutta percha balls also had a smooth, round surface. Eventually, golfers noticed that as the ball’s surface became marked up with use the ball flight was truer. A St Andrews golfer used the claws of a hammer to criss cross grooves over the entire surface of the ball to roughen it up. This was the beginning of experimenting with different cover patterns on the golf ball. Because gutta percha is malleable when boiled, Willie Dunn of Musselburgh discovered he could pour the melted substance into a metal mold and compress it.

The next logical step was to modify the interior of the mold by adding various patterns. Ball makers experimented with unique and exotic cover designs that include: stars, crescents, circles, triangles, commas, diamonds, letters, squares, hexagons, donuts, dimples and others. A ball called “Agrippa” was the first to use a bramble cover, which had small bumps on the exterior instead of grooves. Toward the late 1890s, the bramble ball with its raised round nubs was extremely popular.

Introduction of the guttie caused several changes. The ancient long nose clubs, just right for featheries, were too delicate for use with the harder guttie so new golf clubs were developed with tougher wooden heads and clubmakers saw an opportunity to produce a greater variety of lofted irons. The balls flew further so golf courses needed to be lengthened. Manufacturers and golf pros recognized the new ball presented an attractive new business opportunity so they began to produce great quantities of balls; but, since no standards existed, balls were produced in a variety of sizes, weights, and styles.

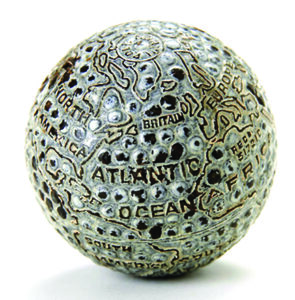

Dozens of unique cover patterns were sold that often command a high price from modern collectors. Three of the most desirable are: Willie Dunn’s Stars & Stripes (1897) bearing a flag pattern; the Map of the World (1905) a sort of mini globe; and a ball by Alexander Henry (1903), with spiral rifle grooves. (See photos next page.)

A Stars and Stripes ball fetched nearly $30,000 at auction in 1996, while a Park Royal sold for more than $35,000.

The Rubber Core Ball

On a hot summer day in 1898, Coburn Haskell of Cleveland, opened a new chapter in golf history. While visiting a friend, Bert Work, at the B.F. Goodrich plant in Akron, Ohio, he began to experiment by tightly winding long pieces of elastic thread into the shape of a golf ball. It was an extremely frustrating exercise since with a single miscue the elastic unwound, flying in all directions. Eventually he mastered the task, most likely with the assistance of some skilled lady employees, according to The Curious History of the Golf Ball, Mankind’s Most Fascinating Sphere (John Stuart Martin, 1968). He created the first rubber core ball, but the tale does not end there. Several additional challenges faced the new ball.

1. The core. Initially, Haskell wound the elastic rubber strands around a piece of rubber that was coated with gutta percha. Later ball makers used a variety of materials for the core, such as rubber, cork, steel, and celluloid. In 1908 Frank Mingay invented and patented a liquid encapsulated core that greatly improved compression at impact, and the ball’s flight became even longer.

2. Compression and elasticity. The elastic threads had to be tightly wound, stretched roughly seven times their original length. This was a slow, tedious, and laborious process done by hand that produced balls with varying degrees of elasticity. A machinist at B.F. Goodrich, John Gammeter, built an ingenious winding machine that automated the process, produced consistent elasticity, and ended the drudgery and inefficiency of hand winding balls. His invention enabled mass production, consistent quality, lower costs and assured the success of the rubber core ball.

3. The cover. When Coburn Haskell invented the rubber core ball, B.F. Goodrich was already making and selling molded gutta percha balls. Quite naturally they chose gutta percha as the cover material for their new Haskell ball. The cover was installed using a grooved mold much the same as had been done with the guttie. However, even though the rubber ball added considerable distance, it tended to duck and bound as had the earliest smooth gutties, earning the nickname “the bounding billy.”

James Foulis Jr., winner of the U.S. Open in 1896, and inventor of the popular “Foulis Club,” a concave mashie niblick with a rounded top and flat sole, discovered that if a bramble cover, similar to the Agrippa pattern, was substituted, the ball’s flight was more predictable. Thus, many of the early rubber core balls bear a bramble pattern cover much like their gutta percha predecessors.

A.G. Spalding and Brothers

Although dozens of companies entered the golf ball business, Spalding played the dominant role. Spalding was the first American company to produce balls, from its Chicopee, Mass. factory. The company played a critical role in promoting golf in 1900 through sponsorship of Harry Vardon’s 30,000-mile, year-long, tour of America and Canada. Unfortunately, Spalding missed a bet by promoting “The Vardon Flyer,” a guttie, just as the superior new Haskell rubber ball was beginning its march to wide acclaim and adoption by everyday golfers and professionals alike.

Spalding was built on enterprise, innovation, and adaptability enabling it to meet changing times. For the next two decades, company agents pursued an aggressive strategy to track, license, and adopt new innovations and developments in the field of golf made by third parties, all the while continually experimenting with its own designs. It acted quickly to obtain a Haskell license and added a strengthened balata cover to its new Spalding Wizard.

In 1906, when British engineer John Henry Taylor invented and patented the dimple or dot faced cover, Spalding quickly recognized this aerodynamic breakthrough and promptly purchased the patent rights. It began to produce the first American-patented dimple balls in 1909.

Similarly, when Mingay patented the liquid core in 1908, Spalding acquired rights to his invention. In the 1920s a chemist from Goodrich figured out to harden the balata ball cover through a vulcanization process. This became known as the Greer cover and Spalding implemented the process on a new ball line it called the Kro-flite.

In 1915, Henry T. Curtiss, manager of Spalding’s Chicopee factory, wrote an article extolling the merits and superiority of the Spalding line of balls, citing the dimple marking, a superior cover, the soft core, hardness of the wind or compression, and the uniformity and consistency of Spalding balls. An article in the August 1903 Fortune magazine seemed to concur, noting, “Golf balls are Spalding sales leaders…” and “Spalding sales represent 50 percent of the entire sport industry’s income…”

The amazing variety of unique cover patterns during this period can be directly linked to Spalding’s ownership of the patent on the dot faced ball, which required other ball makers to experiment with alternatives.

Shown below are a few examples of rare golf balls, their unique covers and auction prices or general estimated value, if available, which varies based on condition.